General tolerances in plastics processing

General tolerances in plastics processing The understanding of general tolerances of plastic parts is not always understood by mechanics used to CNC machining or tolerancing.

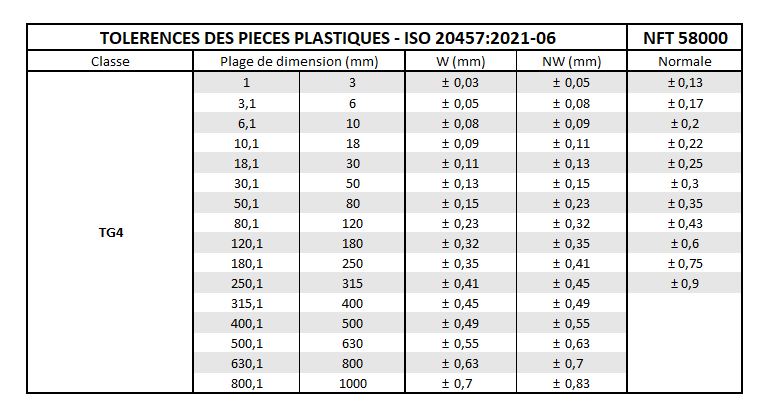

Some French plastics manufacturers also use a French standard (NFT58000), which has been obsolete for almost 20 years! DIN ISO 20547 dating from 2021 is much more suitable for technical materials!

Principle to understand:

Injected thermoplastic materials are first heated and then injected under pressure into a mould cavity. Between the plastic phase (soft material) and the solid phase, the material shrinks during cooling. The shrinkage is taken into account in the design and manufacture of the mould. (Overall, a cavity is made larger than the part...so that the right size is reached during cooling...quite easy isn't it?

tolérance générale

except that ....

- Not all materials have the same shrinkage rate

- Shrinkage is not always the same in length and width of the material flow

- The injection parameters used (pressure, temperatures) have an influence on the shrinkage

- Mould temperature also varies the shrinkage (and also the potential deformation of the parts)

- .... and the list can be much longer...if we also consider that the material supplier also has manufacturing tolerances...as does the mouldmaker...and the moulding company...

Since shrinkage is expressed as % of the length, it is immediately clear that the tolerance will also be proportional to the length of the product...(just as is the case for a geometric tolerance in mechanics, which is proportional to the dimension)..... This being said, we have already destroyed the concept of general tolerance to ± 0.2!

How ISO 20457 works

The first point to note is that the ISO20457 standard is not fixed like the previous one on existing resins since it takes into account intrinsic criteria of the materials and the types of transformation that can be used.

Are you ready? Let's get to the heart of the matter:

The tolerance grid (TG) to be used, will be based on 5 material / process and product criteria combined!

TG = P1+P2+P3+P4+P5

Need an example?

- Injected part (1 Point)

- in ABS (modulus of elasticity: 1600 MPA) (1 Point)

- Shrinkage: 0.7% (1 Point)

- Control of shrinkage (do we have the data sheet?) - (1 Point)

- Commonly used product (normal) - (0 Point)

TG = 1 + 1 + 1 + 1 + 0 = TG4

The standard ISO20457just like its ancestor NFT58000In addition to the above, a distinction is made between dimensions that do and do not include the parting line in the dimension chain.

Faq Plastics

What is NFT 58000 french norm ?

The NFT 58000 standard defines the tolerances applicable to injection-molded plastic parts, depending on the plastic material, dimension and precision class required by the product specifications.

What's the difference between NFT58000 and ISO20457?

The NFT 58000 standard was published in the 1980s, whereas the ISO 20457 standard is much more recent. Furthermore, the NFT58000 standard is only used in France; internationally, the ISO20457 standard is more common!

What impact do tolerances have on manufacturing costs?

The tighter the tolerances, the greater the probability of producing a non-conforming part. It is common to say that to produce a part with a tolerance of ±0.1 mm, you need a machine capable of producing parts to ±0.01 (i.e. 10 times more accurate).

Tolerance and draft angle... how do you do it?

When speaking about plastic moulded part draft angles have to be considered. It is very common to add annotations on part drawing such as : + draft or - draft